The lifespan of a submerged arc furnace lining is affected by a variety of factors, including the quality of the refractory materials, the level of masonry, the furnace drying process, and smelting operations. Some linings can last over 10 years, while others can last only a few months. This wide range in lining lifespan is primarily a significant test of the quality of the refractory materials. Carbon materials are the primary lining material for submerged arc furnaces. carbon blocks, carbon bricks uses. Among them, electric furnace carbon bricks, a special refractory material used to build the bottom and hearth of the submerged arc furnace, have a quality that directly determines the lifespan of the submerged arc furnace lining.

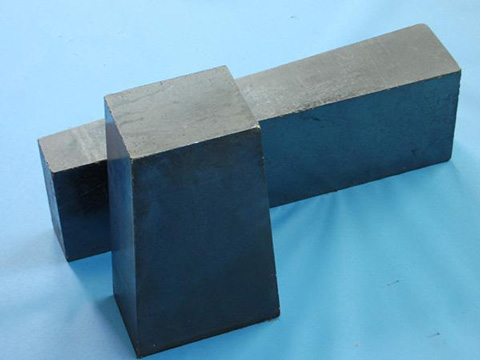

Carbon Bricks for Submerged Arc Furnaces

With the rapid development of high-energy-consuming industries, submerged arc furnaces are becoming increasingly larger, placing increasing demands on the lifespan of furnace linings and furnace bottom safety. Simultaneously, incidents of molten iron penetrating the bottom are becoming more and more frequent, placing higher demands on upgrading furnace lining materials and improving their quality. Carbon bricks must operate at temperatures exceeding 2,000°C and are subject to long-term erosion, penetration, and corrosion from molten iron and furnace charge. When carbon bricks are damaged to a certain extent, preventing the furnace from operating normally, the furnace must be shut down and rebuilt. The service life of carbon bricks is the most important factor affecting the lifespan of an electric furnace. Therefore, improving the oxidation resistance, erosion resistance, and penetration resistance of carbon bricks in electric furnaces is particularly important.

Use of the First Generation of Carbon Bricks

In response to the special requirements of submerged arc furnaces for carbon bricks, and drawing on years of practical production experience, we have developed the first generation of carbon bricks – new high-density, low-porosity electric furnace carbon bricks. These high-density, low-porosity carbon bricks are made from raw materials with high thermal conductivity, low porosity, high bulk density, and strong antioxidant properties. The use of ultrafine powder (98% particle size below 0.045 mm) improves paste forming conditions and fills the micropores between large particles. Additives can reduce the micropores in the carbon bricks. By reselecting and adjusting raw materials, particle size, and mix ratios, and optimizing processes and equipment, we have finally produced electric furnace carbon bricks with a porosity of less than 15% and a compressive strength exceeding 40 MPa, meeting the production needs of submerged arc furnaces. These carbon bricks offer low porosity, high density, high compressive strength, and significantly enhanced resistance to oxidation, erosion, and penetration. The safety, reliability and service life of the furnace bottom of the electric arc furnace have been improved, and the average furnace life has been increased from less than 2 years to 4-5 years.

The Use of Second-Generation Carbon Bricks

As the industry continues to develop, first-generation carbon bricks, while maintaining a certain market share and influence, will face further upgrades to meet evolving market demands. Large-section carbon blocks have long been widely used in developed countries. However, due to limitations in equipment and process technology, most production is limited to small-section carbon bricks (400 mm × 400 mm), which cannot meet the demand for large-section carbon bricks in large-scale submerged arc furnaces. To meet the continuous development of the industry, through repeated exploration and experimentation, accumulated data, and summarized experience, the size of carbon blocks has been gradually increased from 400 mm × 500 mm, 400 mm × 600 mm, 400 mm × 800 mm, 600 mm × 800 mm, and 800 mm × 800 mm, ultimately achieving mass production of large-size carbon blocks of 800 mm × 800 mm × 4000 mm. The development of large-section carbon blocks involves more than simply increasing the size of existing blocks. Instead, it involves a comprehensive transformation and coordination of process technology, raw material preparation, molding equipment, roasting technology, and machining. While increasing the cross-section of the carbon blocks, the original physical and chemical properties are maintained.

The larger cross-section of these carbon blocks reduces gaps in the furnace floor masonry, thereby reducing the risk of molten iron burning through the furnace floor due to gaps. The larger cross-section also increases the weight of the individual carbon blocks, preventing them from drifting. The successful development and widespread use of the 800 mm × 800 mm large-section carbon blocks provide a strong guarantee for extending the life of large-scale submerged arc furnace linings.

Use of Third-Generation Carbon Bricks

Changes in Demand for Carbon Bricks for Submerged Arc Furnaces. Currently, newly built submerged arc furnaces both domestically and internationally are trending toward larger, more enclosed structures, higher power, and greater automation. Large-scale electric furnaces offer high thermal efficiency, high product quality, low unit investment, stable operation, and environmentally friendly performance. As submerged arc furnaces become larger, the corresponding furnace chamber size is also increasing. This places higher demands on the performance of the materials used to build the furnace.

First, the size of the carbon bricks used to build the furnace bottom is increasing, with the largest size reaching 800 mm × 800 mm × 3,700 mm.

As the cross-section and size of the carbon bricks continue to increase, the weight of each brick is also increasing. During the construction of large submerged arc furnaces, gaps can be reduced to prevent brick drift. This improves the utilization rate of fired blanks and reduces waste for manufacturers.

For a furnace with a diameter of 10 m, based on the design drawings for three sizes of carbon bricks: 400 mm × 400 mm × 1200 mm, 400 mm × 820 mm × 1200 mm, and 800 mm × 800 mm × 3700 mm, one layer of 800 mm × 800 mm × 3700 mm bricks is equivalent to two layers of the other two sizes. Based on the total length of gaps between 400 mm × 400 mm × 1200 mm bricks, replacing them with 400 mm × 820 mm × 1200 mm bricks can reduce the gap by 30.8%. Replacing them with 800 mm × 800 mm × 3700 mm bricks can reduce the gap by 72.1%. Taking the total length of gaps in a 400 mm × 820 mm × 1,200 mm carbon brick as a benchmark, replacing it with 800 mm × 800 mm × 3,700 mm carbon bricks can reduce the gap size by 59.7%.

At the same time, with the increasing size of submerged arc furnaces, the diameter and depth of the furnace chamber have increased. As the charge volume increases, the amount of molten iron loaded in the furnace increases, leading to higher production, which in turn increases the pressure on the carbon bricks at the furnace bottom. Due to the increased charge volume, larger electrode size, and higher furnace temperatures in large submerged arc furnaces, the eddy currents of the molten liquid during the smelting process intensify, increasing the impact on the carbon bricks.

As a manufacturer of submerged arc furnace lining materials, we are committed to upgrading our products to better meet customer needs in response to the challenges faced by downstream enterprises in their upgrades and development. For high-quality submerged arc furnace carbon bricks and blocks, please contact Rongsheng. Get free carbon brick pricing!