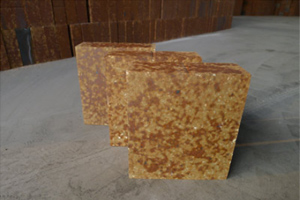

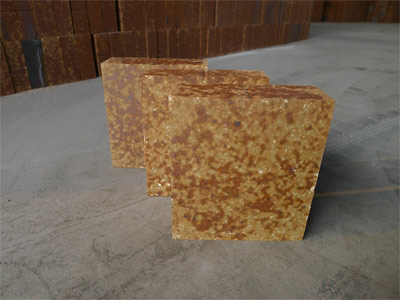

Silica mullite brick is a refractory brick which is composed of mullite and andalusite, silicon carbide and special graded alumina as the main raw materials, which are formed by high pressure molding and high temperature firing.

Silica mullite brick is characterized by good high temperature resistance, wear resistance, corrosion resistance, low thermal conductivity and low energy consumption. At present, silica mullite brick covers the cooling zone and transition zone of most cement kilns. The silica mullite brick not only has good thermal shock resistance, but also the thermal conductivity fully satisfies the use of the cement kiln. According to the use, the temperature outside the cement kiln does not exceed 320 degrees, and the temperature detected after using the silicon brick is basically only 250 -280 degrees, greatly reducing the surface temperature of the kiln cylinder and reducing energy consumption. The heat resistance of the silica mullite brick is also very good, its load softening temperature can reach 1600 degrees, and the carrier in the cement kiln is generally about 1400 degrees, there is no problem in repeated use for 1 year; and its wear resistance is also very good. Fully meet the national standards for refractory materials.

Features of Silica Mullite Bricks:

- Reduce the temperature of the cylinder above 50°C to ensure the safe operation of thermal equipment and reduce the phenomenon of red kiln.

- Improve the heat utilization efficiency of the rotary kiln, reduce energy consumption by more than 5%, and improve the efficiency of the enterprise.

- The overall performance is good, the effective use volume is larger than the composite product, and the wear-resistant period is long.

Technical Parameter of Silica Mullite Bricks:

| Item | RS-AZM1650 | RS-AZM1680 |

| Sic + SiO2 | ≥ 30 | ≥ 32 |

| Al2O3 | ≥ 65 | ≥ 65 |

| Refractoriness Under Load | ≥ 1650 | ≥ 1680 |

| Apparent Porosity (%) | ≤ 19 | ≤ 19 |

| Thermal Shock Resistance | ≥ 15 | ≥ 20 |

| Bulk Density (g/cm3) | ≥ 2.65 | ≥ 2.70 |

| Cold Crushing Strength (Mpa) | ≥ 90 | ≥ 100 |