Fire clay bricks are mainly composed of mullite (25% to 50%), glass phase (25% to 60%) and cristobalite and quartz (up to 30%). Usually, the hard clay is used as raw material, and the mature material is pre-calcined, and then soft clay is used to form a semi-dry method or a plastic mold, and the clay brick product is fired at a temperature of 1300 to 1400 C. It is also possible to add a small amount of a binder such as water glass or cement to make a non-fired product and an amorphous material. It is a commonly used refractory brick in blast furnaces, hot blast stoves, heating furnaces, power boilers, lime kiln, rotary kiln, ceramic and refractory brick firing kiln.

Due to the low softening temperature of the clay brick, the shrinkage occurs at high temperature, the thermal conductivity is 15%~20% lower than that of the silica brick, and the mechanical strength is also worse than that of the silica brick. Therefore, the clay brick can only be used for the secondary part of the coke oven, such as regenerator wall sealing, small smoke lining brick and regenerator grid brick, furnace door lining brick, furnace top and riser lining brick.

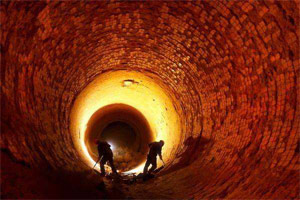

Application:

Technical Parameter of Fire Clay Bricks:

| Item | Fire Clay Brick | |||||||||

| Refractoriness ≥℃ | 1750 | 1730 | 1730 | 1710 | 1710 | 170 | 1690 | 1580 | ||

| Refractoriness Under Load in 0.2Mpa ≥ | 1400 | 1350 | — | 1320 | — | 1300 | — | — | ||

| Permanent | 1400℃ ×2h | 0.1 | 0.1 | 0.2 | — | — | — | — | — | |

| Linear | -0.4 | -0.5 | -0.5 | |||||||

| Change | ||||||||||

| 1350℃×2h | — | — | — | 0.2 | 0.2 | 0.2 | 0.2 | — | ||

| -0.5 | -0.5 | -0.5 | -0.5 | |||||||

| Apparent Porosity % | 22 | 24 | 26 | 24 | 26 | 24 | 26 | 28 | ||

| Compress Strength, kg/cm2 | 300 | 250 | 200 | 200 | 150 | 200 | 150 | 150 | ||