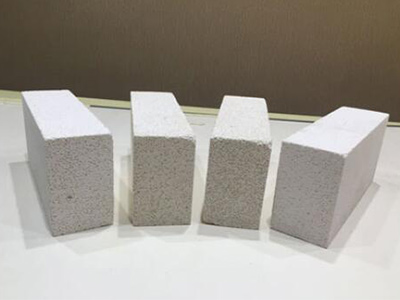

Description For Mullite Bricks

Mullite Bricks are an excellent quality high alumina refractory product contains 65~75% alumina content. Mullite brick is made of mullite as the main raw material which is a very rare kind of quality refractory raw materials, and molded through high temperature firing and pressure. Mullite bricks have advantage performance on furnace and kiln application such as high temperature resistance, chemical and mechanical corrosion, good thermal shock resistance and so on. Some Mullite Bricks with lower alumina content also contain a small amount of glass phase and cristobalite, and some that with higher alumina content also contain a small amount of corundum.

Mullite Bricks Properties

1.Excellent chemical erosion resistance 2.Low thermal conductivity and heat capacity 3.High purity and low impurity content 4.Accurate size and can be cut arbitrarily 5.High strength with good thermal shock resistance 6.Low reheating linear change 7.High temperature resistance and can directly contact with fire 8.High dense structure

Advantage of Rongsheng Refractory Manufacturer

- Provide Customized Refractory Products.

- Best After-Sale-Service.

- Qualified with ISO Certificate, LIRR Test, BV and TUV Certificate.

- Professional Engineers and Advanced Production Technology.

- Sale to Thailand, Indonesia, Pakistan, Saudi Arabia, South Africa, Turkey, Iran, Iraq and etc.

| Mullite Bricks | |||||

| Item | MU 60 | MU 65 | MU 70 | MU 75 | |

| Chemical Composition | Al2O3 | ≥60 | ≥65 | ≥70 | ≥75 |

| SiO2 | ≤35 | ≤33 | ≤26 | ≤24 | |

| Fe2O3 | ≤1.0 | ≤1.0 | ≤0.6 | ≤0.4 | |

| Bulk Density g/cm3 | ≥2.55 | ≥2.55 | ≥2.55 | ≥2.55 | |

| Permanent Linear Change On Reheating (%) 1500℃X2h | 0~+0.4 | 0~+0.4 | 0~+0.4 | 0~+0.4 | |

| Apparent Porosity % | ≤17 | ≤17 | ≤17 | ≤18 | |

| Thermal Conductivity (W/MK) 1000℃ | 1.74 | 1.84 | 1.95 | 1.95 | |

| Cold Crushing Strength Mpa | ≥60 | ≥60 | ≥80 | ≥80 | |

| 20-1000℃ Thermal Expansich10-6/℃ | 0.6 | 0.6 | 0.6 | 0.55 | |

| 0.2Mpa Refractoriness Under Load T0.6 ℃ | ≥1580 | ≥1600 | ≥1600 | ≥1650 | |

| Thermal Shock Resistances 100℃ water cycles | ≥18 | ≥18 | ≥18 | ≥18 | |