Acid-resistant bricks are primarily made from quartz, feldspar, and silicon dioxide, and are produced through high-temperature firing, resulting in a corrosion-resistant material. They are not easily oxidized at room temperature and can withstand alkaline media of any concentration, exhibiting excellent resistance to hydrochloric acid, nitric acid, and warm chloride solutions. However, they are not resistant to molten alkalis at high temperatures. Acid proof bricks are widely used in corrosion protection applications in chemical, petroleum, power, papermaking, metallurgy, chemical fiber, pharmaceutical, fruit juice, and electroplating industries. They also demonstrate high corrosion resistance in underground sewage systems.

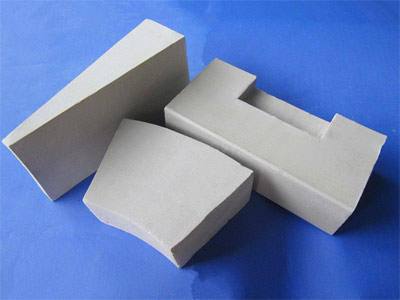

Types of Acid-Resistant Bricks

- Plain acid proof bricks

Plain acid-resistant bricks typically refer to floor anti-corrosion and acid-resistant bricks. These bricks usually have small particles on their surface, providing a certain degree of slip resistance. Therefore, they are often used in factory workshops. They offer excellent corrosion resistance, but cleaning them is relatively difficult.

- Semi-Glazed Acid-Resistant Bricks

Semi-glazed acid-resistant bricks combine the advantages of glazed and plain acid proof bricks. Their surface has a thin glaze, making it smooth to the touch, and also contains granular material. Therefore, they offer excellent slip resistance and are relatively easy to clean.

- Glazed Acid-Resistant Bricks

Glazed acid-resistant bricks have a relatively smooth surface. These bricks are coated with a thick layer of glaze. Therefore, they are very easy to clean and are often used in factories for walls, pool walls, linings, and other areas requiring relatively high cleanliness.

Parameters of Acid-Resistant Bricks

Acid-resistant bricks are widely used in pharmaceuticals, chemicals, papermaking, fertilizers, printing and dyeing, electroplating, nuclear power, food, and beverage industries due to their corrosion resistance, acid and alkali resistance, and high mechanical strength. To better utilize them, it is necessary to understand their various specifications.

- Acid and Alkali Resistance: ≥99.82%

- Water Absorption: ≤0.4%

- Flexural Strength: ≥21.8MPa

- Stain Resistance: Not lower than Level 4

- Freeze-thaw Resistance: No cracks or peeling after multiple cycles

- Resistance to Rapid Temperature Changes: No cracks, peeling, or damage after one test

Characteristics of Acid-Resistant Bricks

The main characteristics of acid proof bricks are as follows:

- Their main component is silicon dioxide, which, after high-temperature firing, becomes a large amount of andalusite. This material has a dense structure and low water absorption, and can withstand alkaline media of any concentration at room temperature. It is widely used in the construction of acid trenches, acid wells, and acid storage tanks.

- They are made primarily from quartz, feldspar, and clay, which are decomposed at high temperatures into corrosion-resistant materials. They possess high acid and alkali resistance, low water absorption, are not easily oxidized, and are not easily polluted. They are widely used in corrosion protection projects in petroleum, chemical, metallurgical, power, chemical fiber, papermaking, pharmaceutical, fertilizer, electroplating rooms, and for towers, pools, tanks, and troughs.

- Their water absorption rate is very low. Water absorption rate refers to the percentage of the product’s weight in water absorbed when the pores are saturated. In my country, bricks with a water absorption rate ≤0.5% are classified as porcelain bricks, and those with a water absorption rate >10% are classified as earthenware bricks.

- It has excellent thermal shock resistance. During production, it underwent 10 thermal shock tests without any cracking or splitting.

- It has excellent gloss, and gloss is one of the standards for judging the quality of polished tiles. Higher gloss indicates better product quality, and vice versa.

Applications of Acid-Resistant Bricks

Conventional acid-resistant ceramic tiles are mainly used in chemical, petroleum, and pharmaceutical applications. Rongsheng‘s acid proof bricks are used as linings for drying towers, absorption towers, and reactors in the metallurgical, chemical, and petrochemical industries. They are also used as lining bricks for corrosion-resistant pools, floors, and passageways. Contact Rongsheng for free samples and quotations.