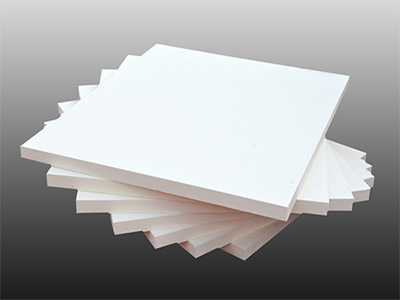

Ceramic Fiber Board

| Classification temperature ( °C) | 1000 |

| Linear shrinkage (%, °C x 24 hrs) | 1.3 (900) |

| Modulus of rupture (kg / cm2) | 5 |

| Shot content (>212 micro meter) (%) | 18 |

| Available size ( mm/pc) |

900 / 1000*600*6 / |

RONGSHENG ceramic fiber boards are rigid products made from ceramic fiber which is vacuum formedwith organic and inorganic binders, with or without mineral fillers. These are manufactured over a wide range of grades densities and hardnesses.

► Application:

♦ Ceramic Fiber Board is made of Alumino-Silicate fibrous wool by vacuum forming process.

♦ Furnace with high temperature and high gas flow velocity

► Characteristic:

♦ Fibers are bonded by binder

♦ Low density and low thermal conductivity

♦ Shorter heat up and cool down time

♦ Resilience and resistance to thermal shock

♦ Greater mechanical strength

♦ Can withstand gas flow velocity of 30 m/sec

♦ Even density, thickness

♦ Flexible and easy to cut or install

♦ Asbestos free

Specifications Of Ceramic Fiber Board:

| 1000 Board | 1260 Board | 1400 Board | 1600 Board | |

| Classification temperature ( °C) | 1000 | 1260 | 1425 | 1600 |

| Bulk density ( Kg/m3) | 250 | 250 | 200 | 180 |

| Linear shrinkage (%, °C x 24 hrs) | 1.3 (900) | 1.1 (1100) | 1.6 (1200) | 1.2 (1400) |

| Modulus of rupture (kg / cm2) | 5 | 5 | 5 | 2 |

| Shot content (>212 micro meter) (%) | 18 | 18 | ||

| Thermal conductivity Kcal/mh °C (W/mK) ,ASTM C201 | ||||

| 250 kg/m3 | 250 kg/m3 | 200kg/m3 | 180kg/m3 | |

| mean 400 °C | 0.08 | 0.09 | ||

| mean 600 °C | 0.13 | 0.14 | 0.1 | 0.12 |

| mean 800 °C | 0.2 | 0.18 | 0.14 | 0.16 |

| mean1000 °C | 0.2 | 0.21 | ||

| Chemical composition (%) | ||||

| Al2O3 | 40.1 | 44 | 52 | 58 |

| SiO2 | 54.3 | 54 | 47 | 41 |

| Available size ( mm/pc ) | 900 / 1000*600*6 / 12.5 / 20 / 25 / 30 / 40 / 50 ; 1100*700*25 / 50 | |||